Utilizing Swagelok® seamless tubing solutions can dramatically improve your productivity. Tubing systems are fast to install, and bending tubing, rather than installing elbow fittings, can improve performance and reduce the number of connections in a system. Further, Swagelok® tube fittings are remakeable, which reduces the time required to maintain or modify systems. This means you can install more systems in less time, and re-allocate saved resources to other areas of your plant. If you are an engineer, manager, pipe fitter, or contractor who is feeling the squeeze of tight budgets, short staff, and increasing workloads, we have three words for you: simpler, safer, faster.

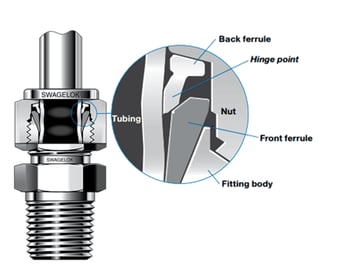

You can create an engineered fluid system with reliable tubing and fittings. Swagelok tube fittings have a grip-type design that uses a unique “hinging and colleting” action to achieve optimal performance in three key areas:

We can help simplify the selection process with our understanding of materials selection.

Discover the advantages of our tube fittings and how they are designed for quality and reliability.

Use this resource to help select the proper hose and flexible tubing solutions for your fluid system.

Quick assembly and reassembly using only standard wrenches make our fittings easy to install. Our expert training equips your workforce with essential skills for installing fittings across all your applications.

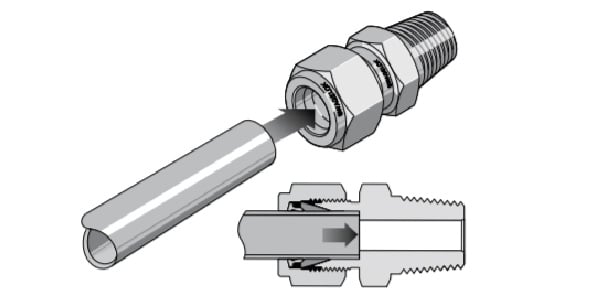

Swagelok tube fittings 1 in./25 mm and smaller can be installed quickly, easily, and reliably with simple hand tools. Over 1 in./25 mm sizes require use of a hydraulic swaging unit to swage the ferrules onto the tubing. The tube fitting instructions below are for illustrative purposes only. For complete installation instructions, including instructions when using a hydraulic swaging unit, please reference the Gaugeable Tube Fittings and Adapter Fitters catalog on swagelok.com.

Fully insert the tube into the fitting and against the shoulder; rotate the nut finger-tight.

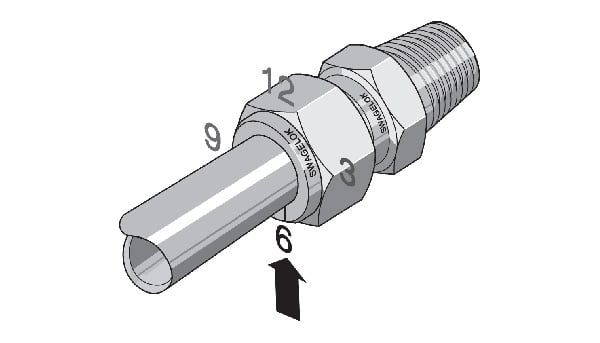

Mark the nut at the 6 o’clock position.

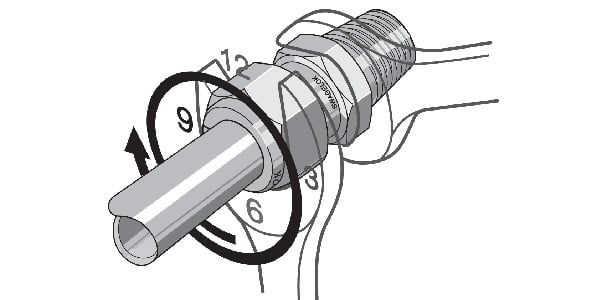

While holding the fitting body steady, tighten the nut one and one-quarter turns to the 9 o’clock position.

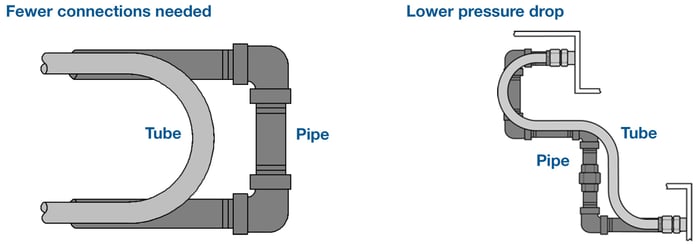

One reason to choose tubing is because of its bendability and routing capabilities, which can help operators achieve more intricate and efficient fluid system design with fewer connection points.

Fewer connections: Fewer individual components means a lighter system and a lower installation cost.

Time savings: Tube bends can save operators time by eliminating the need to cut, deburr, and install a new fitting for every simple directional change.

Less turbulence: Bends allow fluids to flow more easily than through a series of multiple fittings.

Many facilities depend on fluid delivery sent through piping systems. Unfortunately, cutting, welding, and threading hard pipe is not a quick process. It is both slow and labor intensive. A better alternative may be seamless tubing. Seamless tubing, instead of hard pipe, can greatly simplify installation and plant maintenance.

Seamless tubing has fewer connections, which equals fewer potential leak points. In addition, tubing is very adaptable and can be bent around many obstructions. Sharp bends and discontinuities of piping systems are not present in the gradual bends of a tubed system.

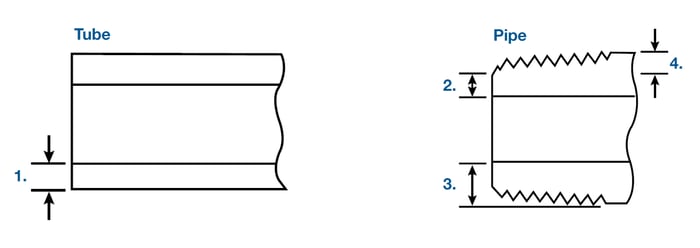

Full wall thickness of tubing is used in containing pressure since no threading is necessary. Threading reduces effective wall thickness in piping. The lighter weight of the tubing provides many benefits. Tubing is less expensive to transport, is easier to assemble, requires less support, and occupies less space.

In the tube illustration below, notice: (1) Full wall thickness of tubing is used to contain pressure.

In the pipe illustration, however, notice: (2) Wall thickness needed to contain pressure; (3) Wall thickness of pipe that must be used; (4) Extra pipe wall thickness required for threading.

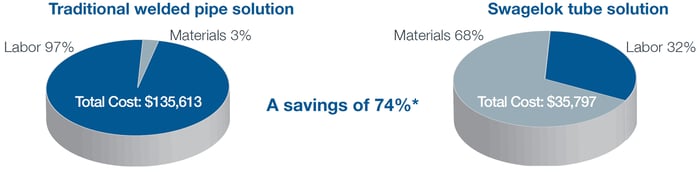

Seamless tubing can offer a significant reduction in time and labor. In fact, 74% of the overall installation costs can be saved by using tubing.* Consider this example, which illustrates how tubing can be more cost effective even with greater up front material costs:

*Estimate performed by Mechanical Contractor for 150lb Stainless Steel Steam System.

While pipe and tubing are often designed to serve the same purpose, the two differ in many ways. Several key areas of difference include:

Tubed systems are generally much more reliable than piped systems and significantly easier to maintain. Quality tube fittings consistently outperform threaded connections and are much easier to service when necessary. Tubed systems can utilize bends to reduce the number of connections. Fewer connections means fewer potential leak points and also reduces component costs. Tubing bends also create less pressure drop than pipe elbows. Less pressure drop and fewer leaks equals better system performance.

Now that you're ready to add seamless tubing to your fluid system, look to Swagelok Minnesota | North Dakota | Appleton to fill all of your tubing needs. We offer:

Support System (weld plates, tube supports, pipe supports, and more)

We can support your success wherever it takes you. Our associates work together to provide factory support, field engineering, technical services, coordinated deliveries, inventory replenishment, and a range of special expertise, all designed to take the pressure off you.

Design consultation and construction of high-quality standard and configurable fluid and sampling systems assemblies.

Boost system safety, performance, and efficiency with prioritized and actionable recommendations personalized for your business.

Enhance your team's critical skills for developing, building, and maintaining high-performing fluid and sampling systems.

.png?width=700&height=350&name=image%20(15).png)

Lorem ipsum dolor sit amet, consectetur adipisicing elit

.png?width=700&height=350&name=image%20(14).png)

Lorem ipsum dolor sit amet, consectetur adipisicing elit