Power

Connect, Convey, Control, Comply, Customize

No matter what segment of the power industry you operate in, Swagelok Minnesota | North Dakota | Appleton stands behind you with the highest levels of quality, reliability, and performance. We are backed by 75+ years in the industry, and our products meet all the key standards, including ASME Section III.

In addition, our products and services will help increase your system's efficiency, thus reducing your operating costs—you might even say your costs per megawatt. We can help you increase accurate measurement, identify the root cause of inefficiencies in your facilities, and keep you performing in regulatory compliance, all while maintaining a safe work environment. Now that's a bright idea.

Connect

Swagelok tube fittings feature a robust tube grip, leak-tight gas seals, and excellent vibration resistance—even in harsh or high-stress nuclear environments. Sizes range from 1/16 to 2 in. and 2 to 50 mm in a variety of materials, including controlled 316 stainless steel. Expect the same quality in our quick-connects.

Convey

Whatever your application, Swagelok Minnesota | North Dakota | Appleton has the small-bore and flexible tubing and hoses to form the backbone of your fluid delivery system. Small bore (up to 2 in. [50 mm] O.D.) tubing reduces the number of connections and potential leak points for greater system integrity. All our products are backed by the Swagelok warranty.

Control

Get precise control with the right valves, manifolds and pressure regulators for your application. Choose from instrumentation and process valves and manifolds.

Comply

Swagelok tube fittings meet ASME specifications and are available as nuclear ASME boiler pressure vessel code Section III, class 1 certified in 316 stainless steel. Swagelok Company works with standards organizations around the world to provide you with products that meet your exact requirements.

Customize

From project start to completion, sometimes you need to work with a supplier that provides a full range of products and solutions. That can even include consultation on a project, custom wiring, third-party components or automation. Swagelok Custom Solutions refers to our expert capability to supply design and assembly services using Swagelok products and other customer specified components. Swagelok Minnesota | North Dakota | Appleton guides you every step of the way, from the design all the way through to execution.

Applications

Every day, Swagelok Minnesota | North Dakota | Appleton supports a broad range of power industry applications including:

- Boilers

- Continuous emission monitoring systems (CEMS)

- Feedwater systems

- Floodgates (stop gates) in dams

- Heat recovery steam generators (HRSG)

- Industrial gas turbines

- Instrumentation piping

- Lube oil skids

- Peaking units

- Pumps

- Small modular reactors (SMRs)

- Smokestack scrubbers

- Steam and water analysis systems (SWAS)

- Water quality monitoring systems (Degas analysis)

Products

Our products are supported worldwide by 200-plus authorized Swagelok sales and service centers and are backed by the Swagelok Limited Lifetime Warranty. From commonly used products to custom components and assemblies, everything we design, manufacture, and build is to ensure the highest level of application, process, and instrumentation integrity. This listing is only a highlight of some of the products available for fuel delivery, gas distribution, steam sampling, water sampling, CEMS, lube oil, and other critical power plant systems. We also provide solutions for boilers, generators, industrial gas turbines, and an array of rotary equipment. Many products are designed to ASME nuclear codes and standards.

Filters

Avoid particulate contaminants leading to inaccurate analyzer readings or other problems downstream with particulate filters and coalescing filters that are designed to preserve the integrity of your power plant processes.

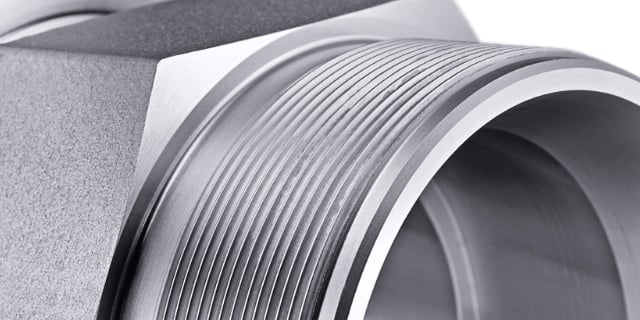

Fittings

Leak-tight fittings are fundamental to a worry-free operation. Find tube fittings, transmitter calibration fittings, PFA fittings, and more for standard applications or where reactive and corrosive chemicals are a concern. Many alloys and configurations are available.

Hoses and Flexible Tubing

Choose from a variety of core materials, reinforcement styles, and end connections. Get bulk hose, hose assemblies, and custom hose lengths in sizes 1/8 to 2 in. Also find metal core hose and PTFE core hose, along with PFA and vinyl flexible tubing for even more chemically resistant options for low-pressure applications.

Pressure Gauges

We have a variety of gauges designed for all conditions from low pressure to severe service. Multiple-mount configurations also make Swagelok gauges convenient to install. Additional measurement devices include pressure transducers, flow sensors, and thermometers.

Quick Connects

Connect quickly and with confidence using our wide variety of quick connect configurations to reduce spillage and air inclusion in your system. We offer full-flow, instrumentation, miniature, and PTFE-sealed Quick Connects.

Regulators

Get precise control with the right pressure regulators. Swagelok pressure-reducing, back-pressure, and specialty regulators are capable of handling a wide range of pressures and flows to help you safeguard your facility.

Small-Bore Tubing

We have the small-bore tubing to form the backbone of your fluid delivery system. Compared to conventional piping, small-bore tubing (up to 2 in. [50 mm] O.D.) reduces the number of connections and potential leak points for greater system integrity. No welding, cutting, or threading of pipe means less required labor, lower installed costs, and no fire watch needed.

Valves

The true cost of a valve is what goes into maintaining or replacing it over time. Swagelok means lasting performance. Turn to us for process and instrumentation ball valves, check valves, needle and metering valves, relief valves, plug valves, bleed and purge valves, and bellows-sealed valves as well as manifolds for process analyzer applications.

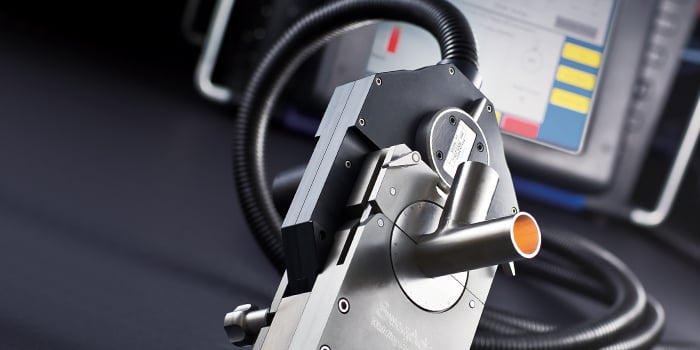

Welding System

Weld precisely and consistently with our orbital welding system, which provides cost-effective, reliable orbital gas tungsten arc welds (GTAW) for both tubing and pipe. Make quality welds with fewer preparations than manual methods. Orbital welding also poses less fire hazards, helping you prevent incidents and injuries.

Services

We provide technical consulting to the energy generation, storage, and distribution sector that improves fluid system safety, efficiency, reliability, and sustainability. Across our service area, power plants and facilities of many types protect their critical infrastructure with solutions and insight from our engineers.

Design and Assembly

Get the custom assembly your power plant needs. We take ideas from concept to creation and reduce your costs by reducing in-house R&D effort, component handling, QA inspections, rework, and assembly time. Let us focus on planning and integration so you can focus on other priorities.

Evaluation and Advisory Services

Our site surveys look for opportunities to align best practices with your systems. We help by identifying leaks, prioritizing areas of concern, documenting problems, and charting steps to improve system health. Whether your focus is design, production, or MRO, you can count on Swagelok to drive efficiency.

Field Engineering

Our field service team is a resource for customers who value professional consultation about changing pressure, temperature, and flow requirements for their critical processes. We can help you improve plant safety and fluid system health, reduce emissions, onboard new personnel, or help with fluid subsystem assembly.

Locally Stocked Inventory

We can assist you with inventory optimizing, organizing, labeling, and reordering to help prevent stockouts and reduce the risk of downtime. Eliminate transaction fees and avoid being bogged down by surplus items with carefully managed onsite inventory services.

Fluid System Training

Equip personnel with the skills to ensure a smooth operation. Our training courses range from tube fittings essentials to tube bending to fluid system installation. Receive expert guidance on valve selection, regulator use, hose management, and materials science. Also learn about process analyzer, sampling, and steam systems.

.png?width=700&height=350&name=image%20(15).png)

.png?width=700&height=350&name=image%20(14).png)