How to Improve Your Maintenance Program with Valve and Hose Tags

Hose Reinforcement 101: How to Make a Strong Choice for Your Application

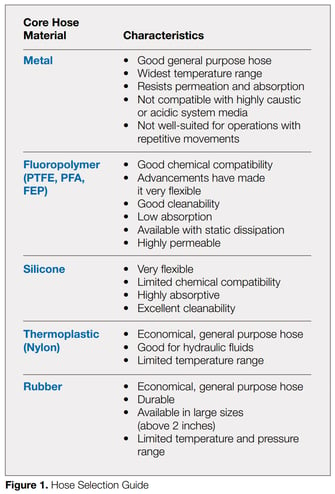

Industrial Hose Replacement: Core Tube Material Considerations

Reviewing Flexible Hose End Connection Types and Use Cases

How an Industrial Hose Maintenance Plan Could Save Your Plant Thousands of Dollars

.jpg?width=640&height=320&name=CAD%20Files%20and%20Drawings%20(1).jpg)

.png?width=700&height=350&name=image%20(15).png)

.png?width=700&height=350&name=image%20(14).png)