Pulp & Paper

Get on the Same Page with Your Supplier

Effective pulp and paper operations—batch and continuous processing, fluid flow, heat and mass transfer, mixing, separation, utilities, and more—depend on high-integrity fluid system components. At Swagelok Minnesota | North Dakota | Appleton, we're committed to addressing all the needs of pulp and paper mills, so we bring the solutions, training, and services needed to benefit equipment, people, and the environment.

- The reliability of our valves and fittings help pulp and paper mills reduce emissions, maintain compliance with environmental regulations, and earn government rebates

- Our applications can improve mechanical seal efficiencies

- Our components used in steam systems and for condensate return contribute significantly to leak-tight performance and energy savings

- We also provide consultation, engineering assistance, as well as training, all to equip your team with the skills to work safely and efficiently

- Our onsite audits can identify problem areas that can impact cost, safety, productivity, and yields

- The full spectrum of our advisory services can further reduce the potential for costly leak detection and repair (LDAR) procedures

We know the how hard the systems in pulp and paper mills work, with steam, chemicals, temperature, and vibration all presenting countless challenges for machines and instrumentation. Our solutions-first approach helps you stay in step with changing Technical Association for the Pulp, Paper and Converting Industry (TAPPI) standards for ISO quality management, manufacturing standardization, and workplace health and safety.

Let us help your facility perform under pressure and responsibly meet production goals without sacrificing speed or quality.

Applications

Swagelok Minnesota | North Dakota | Appleton supports all the equipment and process support systems found in pulp and paper mills, plants, and facilities, including:

- Agitators

- Cleaning machines

- Coaters

- Compressed air systems

- Deflakers

- De-inkers

- Dispersion systems

- Dryers

- Forming (Fourdrinier) machines

- Finishing equipment

- Headbox units

- Hydraulic systems

- Lubricating systems

- Paper-making machines

- Presses

- Pulpers

- Reject handlers

- Steam systems

- Stock preparation machines

- Suction rolls

- Thickeners

- Wastewater filtration systems

Products

Many pulp and paper facilities find value in our products that help them meet a variety of industry applications. We offer a complete line of fluid system components, including fittings, valves, and hose products, all backed by our Limited Lifetime Warranty.

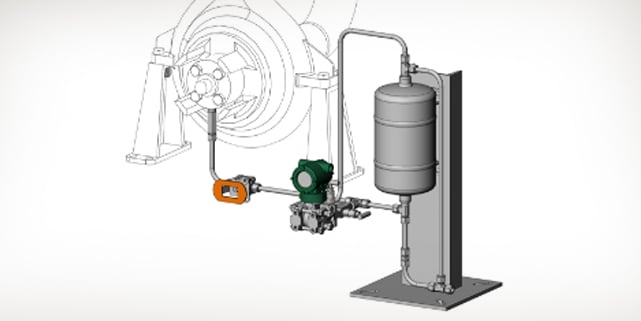

ANSI Pump Flush Plans

Our team of experts can help design and construct safe-to-operate, easy-to-maintain mechanical seal support systems including ANSI pump flush plans. We can help you keep pulp and paper machines and rotating equipment online and operating efficiently with mechanical seal support kits and assemblies.

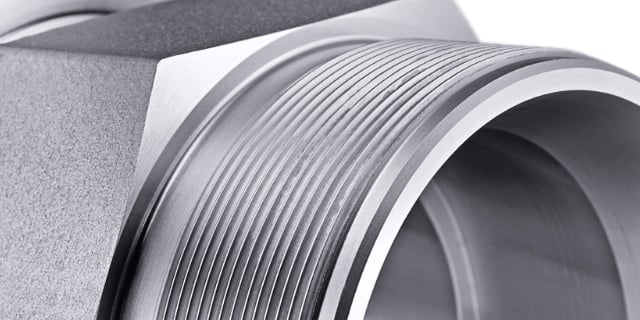

Fittings

Swagelok® tube fittings deliver a leak-tight, gas-tight seal that is resistant to vibration fatigue. Medium- and high-pressure fittings, PFA fittings, pipe fittings, weld fittings, and many others can be used on a variety of thick- or thin-walled, hard or soft tubing while resisting the effects of pressure and thermal cycling. Our fittings are available in a variety of alloys.

Hoses & Flexible Tubing

PTFE and PFA core hoses provide flexibility and chemical compatibility for safe transport of fluids. We also offer thermoplastic and nylon hose for hydraulic needs, flexible but kink-resistant. Swagelok® hoses and flexible tubing are trusted to perform where liquids and gases are crucial to operations.

Leak Detectors, Lubricants, and Sealants

Liquid leak detectors can show you which fluid system connections are leaking, and our pipe thread sealants, PTFE tape, and thread lubricants can help prevent leaks from forming during installation. We can help you reduce your operating costs while making the health and wellness of your team a top priority.

Measurement Devices

We have pressure gauges and transducers designed to provide accurate and dependable measurement for pulp and paper processing and manufacturing. Many range, dial size, connection, and mounting options are available. Additional devices include variable area flow meters, flow sensors, and thermometers.

Regulators

Get the set of capabilities you need from your regulators to keep your facility operating at peak efficiency. Swagelok® pressure-reducing, back-pressure, and specialty regulators maintain pressure and minimize droop over a wide range of pressures and flows. Let our team help you find the right regulator for your pulp and paper plant's conditions and system applications.

Sample Cylinders

A wide selection of sample cylinders that are compliant with various transportation industry standards helps you overcome the challenges related to chemical transfer. These durable, pressure-rated metal cylinders also prevent samples from escaping during grab sample system operation, and they are easy to clean.

Tubing and Accessories

Source reliable tubing from us, including support systems, swaging tools, tube benders, and tube cutting and preparation tools. Our catalogs contain detailed product information including materials of construction, pressure and temperature ratings, and tubing options that allow you to build systems that last.

Valves

The true cost of a valve includes what goes into maintaining or replacing it. We design our products for lasting performance. Meet regulatory standards with valves with low-emission certification. Turn to us for manual and automated ball valves, check valves, needle and metering valves, relief valves, and plug valves. Also find test valve assemblies designed to be used with steam traps.

Engineering Services

Pulp and paper facilities are facing many pressures, from increasing regulatory standards to an overall loss of fluid system knowledge. This skills gap, coupled with pressure to grow profits, has many organizations looking for ways to train employees and free-up their team. Take advantage of the expertise that our engineering services provide.

Design and Assembly Services

Swagelok offers custom assemblies that support your unique needs. Application specialists match your need to a proven solution or take your concept and provide you with a finished product. With our services, you lower your costs by reducing your in-house component inspections, QA effort, component handling, assembly time, and rework and scrap.

Essentials Training

Turn to us for practical training courses designed for engineers, supervisors, and others involved with fluid system installations and inspections. Help your staff build confidence in their skills by building a basic knowledge of fittings, valves, hoses, and more. All courses are led by Swagelok-certified instructors. Ask our team about onsite and virtual opportunities.

Hose Management

Get guidance on hose selection, installation, inspection, and maintenance procedures to improve hose life and performance, as well as minimize the chances of expensive or dangerous failures. Our hose advisory services are engineered to take the pressure off you and reduce wasteful spending on damaged or failed hose.

Locally Stocked Inventory

We can assist you with inventory optimizing, organizing, labeling, and reordering to help prevent stockouts and reduce the risk of downtime. Eliminate transaction fees and avoid being bogged down by surplus items with carefully managed onsite inventory services.

Materials Science Training

Choosing the right corrosion-resistant materials helps keep fluid systems leak-tight. Learn which alloys resist corrosion and how industry standards impact your choices. Swagelok® materials science training is for technical associates, chemists, and anyone involved in the material selection process.

Steam Audits

Steam and condensate specialists can help you conduct a detailed assessment of your plant’s systems and components, document and tag areas needing attention, and share best practices for repair and maintenance. Optimal steam system performance in line with design specifications can create bottom-line increases in productivity.

.jpg?width=641&height=321&name=Bbox_2_MaterialsScience%20(1).jpg)

.png?width=700&height=350&name=image%20(15).png)

.png?width=700&height=350&name=image%20(14).png)