Mechanical Seal Support Systems

Seal Support Systems for Pumps, Agitators, and Mixers

Seal support systems are designed to support a specific mechanical seal and set of process conditions. These systems supply either gas or liquid to the mechanical seal to regulate the environment in which the seal operates.

If the seal system fluid is dirty or contains particulate, seal life can be negatively affected. Similarly, delivering the fluid at the wrong pressure or temperature can cause premature or even catastrophic seal failure. That's why making sure your seal support system is properly designed and installed is critical to keep your rotating equipment available for production.

Wondering where to start with your seal support system? We can help. Access our Mechanical Seal Seal Support Systems eBook for tips on:

- Reducing leak points

- Simplifying installation and maintenance

- Adherence to API 682-recommended best practices

Swagelok® Mechanical Seal Support Systems

Swagelok seal support systems are guided by API 682 and are offered as kits and assemblies. If you are tasked with keeping rotating equipment online and operating efficiently, discover what sets our seal support systems apart:

Designed for reliability and maintenance

- Locally available critical spares – you’ll always have the components you need

- Certified engineers and technicians work with you to meet your system requirements

- Quick turnaround and fast delivery times

Designed for appropriate flow

- Local, customizable, and repeatable API 682 plans for efficient system operation

- Optional additional instrumentation provides clear indication of system performance

Designed for system safety

- Design options allow for customization to suit many challenging applications

- Built with high-quality components

- Backed by the Swagelok Limited Lifetime Warranty

- Reduces potential leak points where costly leaks can occur

Guided by API 682

Swagelok seal support system designs avoid pipe threads and limit the number of connections wherever possible. Based on the fourth edition, the standard design for each plan includes the minimum arrangement of components as detailed in the fourth edition of the API 682: Pumps - Shaft Sealing Systems for Centrifugal and Rotary Pumps.

Learn more about how our configurable, locally available, and reliable systems are better by design.

Seal Plan Kits

Seal plan kits (SPK) are a collection of components that are used to connect the seal support plan to the pump. Each kit contains everything needed for proper installation, including an engineered drawing. For projects or turnarounds, seal plan kits can be used to standardize how plans are connected to the pump.

Kits also adhere to API best practices by showing technicians where to bend tubing to eliminate potential leak points through the reduction of elbow fittings and pipe threads.

Seal Plan Assemblies

Seal plan assemblies (SPA) are panels, seal pots, or skid systems that comprise the majority of the API seal support plans. The seal plan assembly ordering numbering structure allows users to select a variety of configurations and additional system components to meet specific site or application requirements. Options and configurations not listed in the ordering numbering structure are also available.

Seal plan assemblies can be ordered alone or with the associated field installation kit to provide a standard installation for site personnel.

When procuring seal plan assemblies for pump installations or retrofits, please contact us to ensure the proper amount of tubing and tube support materials are provided for a safe and effective installation.

Swagelok Components

Integral Orifice Flange Adapter

Replace threaded or welded flange assemblies with a one-piece flange adapted with integral orifice.

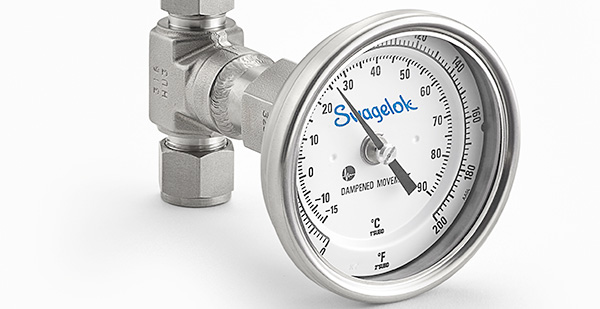

Thermowell Tee

Reduce threaded connections and monitor temperature with integrated thermowell pre-welded into tube fitting for ease of installation.

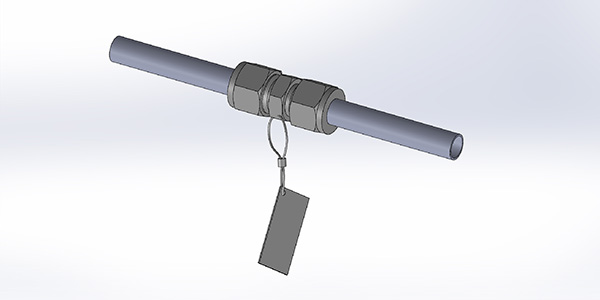

Orifice Union

Easily add an orifice to a flush system with the orifice union. This fitting makes welding bulky flange assemblies unnecessary. Tagged for visual identification.

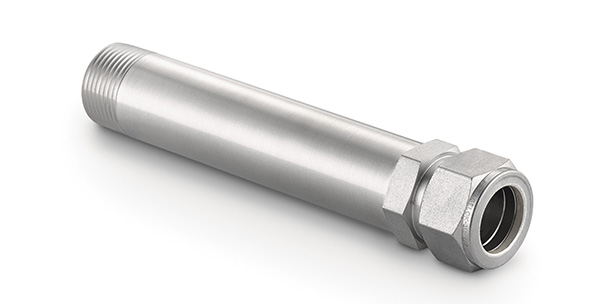

Extended Male Connector

Eliminate threaded pipe and potential leak points with a single fitting. Available in 4-inch and 6-inch lengths to allow you to clean the shroud and go straight from the gland to your tubing run in one piece.

All Swagelok Components

Choose from a wide variety of high-quality, reliable Swagelok components designed to provide lasting performance in your fluid system applications.

.png?width=700&height=350&name=image%20(15).png)

.png?width=700&height=350&name=image%20(14).png)