Your fluid systems can't fail - and they can't leak. A leaky fitting can be expensive and dangerous. System leakage most often occurs at the point of connection in a system. These connection points are where fittings under stress can fail. Reliable fittings, then, are crucial. With Swagelok tube fittings, however, you'll have peace of mind for numerous reasons:

When you need fittings for your fluid system that can withstand corrosive environments, extreme temperatures, or high pressure turn to Swagelok. Customers from a variety of industries trust our fittings for their leak-tight integrity, ease of installation, and availability.

Discover the Swagelok tube fitting advantage and the reasons why so many customers turn to Swagelok when quality, reliability, safety, and ease of installation matter most:

Quick assembly and reassembly using only standard wrenches make our fittings easy to install. Our expert training equips your workforce with essential skills for installing fittings across all your applications.

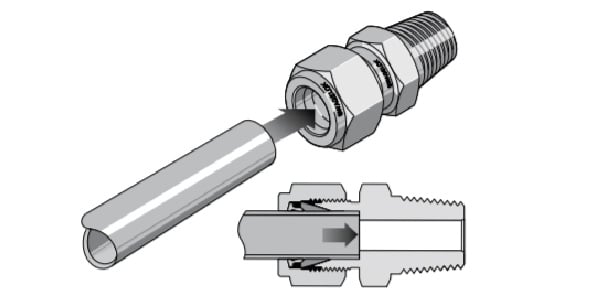

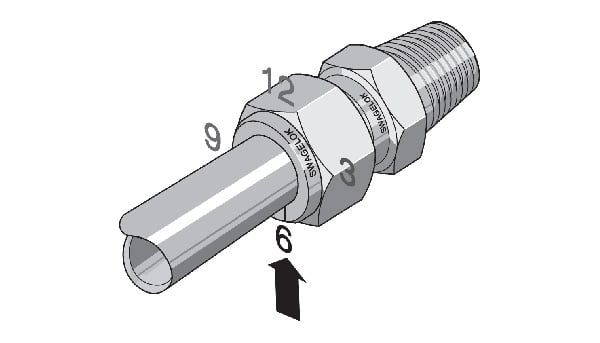

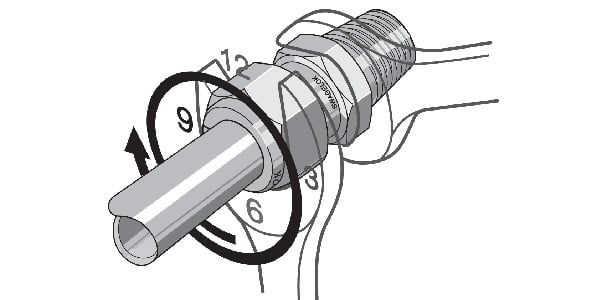

Swagelok tube fittings 1 in./25 mm and smaller can be installed quickly, easily, and reliably with simple hand tools. Over 1 in./25 mm sizes require use of a hydraulic swaging unit to swage the ferrules onto the tubing. The tube fitting instructions below are for illustrative purposes only. For complete installation instructions, including instructions when using a hydraulic swaging unit, please reference the Gaugeable Tube Fittings and Adapter Fitters catalog on swagelok.com.

Fully insert the tube into the fitting and against the shoulder; rotate the nut finger-tight.

Mark the nut at the 6 o’clock position.

While holding the fitting body steady, tighten the nut one and one-quarter turns to the 9 o’clock position.

Well-trained associates are valuable assets that can save your company money and increase the productivity and safety of your workplace. Our trainers can provide you, your associates, installers, and maintenance vendors with a wide range of training to minimize installation, maintenance errors, and ensure your system maintains its reliability.

What to expect from our hands-on training courses:

We can help simplify the selection process with our understanding of materials selection.

We can support your success wherever it takes you. Our associates work together to provide factory support, field engineering, technical services, coordinated deliveries, inventory replenishment, and a range of special expertise, all designed to take the pressure off you.

Design consultation and construction of high-quality standard and configurable fluid and sampling systems assemblies.

Boost system safety, performance, and efficiency with prioritized and actionable recommendations personalized for your business.

Enhance your team's critical skills for developing, building, and maintaining high-performing fluid and sampling systems.

.png?width=700&height=350&name=image%20(15).png)

Lorem ipsum dolor sit amet, consectetur adipisicing elit

.png?width=700&height=350&name=image%20(14).png)

Lorem ipsum dolor sit amet, consectetur adipisicing elit